- Comparison of different types of lasers used for cleaning

- Cost-effectiveness of laser cleaning

- Future developments in laser cleaning technology

- Laser cleaning for cleaning electronic components

- Laser cleaning for removing scale from pipes

- Laser cleaning for cleaning glass surfaces

- Laser cleaning for cleaning jewelry

- Laser cleaning for removing contaminants from 3D printed parts

Comparison of different types of lasers used for cleaning

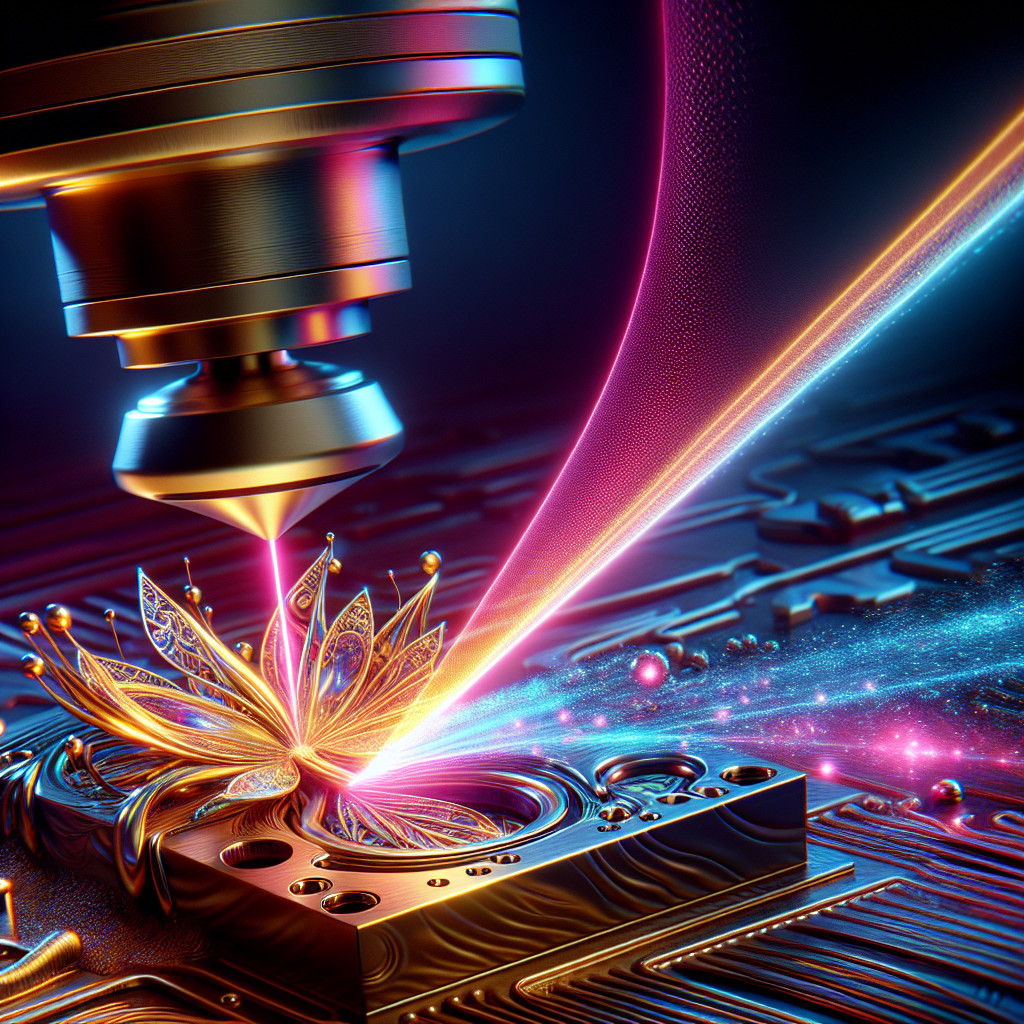

Cleaning with lasers has become a popular method for removing dirt, grime, and other contaminants from various surfaces. There are several types of lasers that can be used for cleaning, each with its own advantages and disadvantages. In this article, we will compare different types of lasers used for cleaning and discuss their applications.

1. CO2 lasers:

– Emit a wavelength of around 10.6 micrometers

– Effective for removing organic contaminants

– Can be used on a wide range of materials, including metals, plastics, and ceramics

– High power output allows for fast cleaning speeds

2. YAG lasers:

– Emit a wavelength of around 1.06 micrometers

– Ideal for removing inorganic contaminants, such as rust and oxides

– Can be used on delicate materials, such as glass and semiconductors

– Precise control over pulse duration and energy output

3. Fiber lasers:

– Emit a wavelength of around 1.06 micrometers

– High beam quality allows for precise cleaning

– Can be used for both surface cleaning and paint removal

– Compact and portable design

4. Excimer lasers:

– Emit ultraviolet wavelengths for precise cleaning

– Ideal for removing thin layers of contaminants

– Used in semiconductor and electronics manufacturing

In conclusion, each type of laser has its own strengths and weaknesses when it comes to cleaning. CO2 lasers are versatile and powerful, making them suitable for a wide range of applications. YAG lasers are ideal for precision cleaning of delicate materials. Fiber lasers offer high beam quality and portability, while excimer lasers are best suited for removing thin layers of contaminants.

#laser #cleaning #CO2 #YAG #fiber #excimer

frazy kluczowe:

– Advantages and disadvantages of CO2 lasers for cleaning

– Applications of YAG lasers in precision cleaning

– Fiber lasers for surface cleaning and paint removal

– Excimer lasers for semiconductor manufacturing and electronics cleaning.

Cost-effectiveness of laser cleaning

Benefits of laser cleaning:

- Efficiency: Laser cleaning can remove contaminants quickly and effectively, reducing the time and labor required for cleaning.

- Precision: Laser cleaning can target specific areas without damaging the surrounding surface, making it ideal for delicate materials.

- Environmentally friendly: Laser cleaning does not require the use of chemicals or solvents, reducing the impact on the environment.

- Cost-effective: While the initial investment in laser cleaning equipment may be higher, the long-term cost savings from reduced labor and materials make it a cost-effective option.

Cost comparison:

When comparing the cost of laser cleaning to traditional cleaning methods, it is important to consider the overall cost of ownership. While laser cleaning equipment may have a higher upfront cost, the savings in labor and materials over time can make it a more cost-effective option.

Case studies:

Several case studies have shown the cost-effectiveness of laser cleaning in various industries, including automotive, aerospace, and manufacturing. In one study, a manufacturing plant was able to reduce cleaning time by 50% and save over $10,000 per year in labor costs by switching to laser cleaning.

Conclusion:

Laser cleaning is a cost-effective and efficient cleaning method that offers numerous benefits over traditional cleaning methods. While the initial investment may be higher, the long-term savings in labor and materials make it a worthwhile investment for many industries.

#laser cleaning, cost-effectiveness, efficiency, precision, environmentally friendly, case studies

#long-tail phrases: cost savings from reduced labor, environmentally friendly cleaning method, precision cleaning technology.

Future developments in laser cleaning technology

1. Increased power and efficiency: As laser technology continues to improve, we can expect to see lasers with higher power outputs and greater efficiency. This will allow for faster and more thorough cleaning of surfaces, making laser cleaning an even more attractive option for a wide range of applications.

2. Enhanced precision: will also focus on improving the precision of the cleaning process. This will allow for more targeted cleaning of specific areas, reducing the risk of damage to surrounding surfaces.

3. Integration with automation: As automation becomes more prevalent in manufacturing and other industries, we can expect to see laser cleaning technology integrated with automated systems. This will allow for more efficient and cost-effective cleaning processes, with minimal human intervention required.

4. Development of new applications: With advancements in laser technology, we can expect to see the development of new applications for laser cleaning. From delicate medical devices to large industrial machinery, laser cleaning technology will continue to expand its reach.

5. Improved safety features: Safety is always a top priority when it comes to laser technology, and will focus on improving safety features. This will help to ensure that laser cleaning remains a safe and reliable option for a wide range of applications.

In conclusion, the future of laser cleaning technology looks bright, with advancements in power, precision, automation, applications, and safety on the horizon. As these developments continue to unfold, we can expect to see laser cleaning technology become an even more versatile and effective tool for a wide range of industries.

#laser #cleaning #technology

Future developments, laser cleaning, advanced precision, automation integration, safety features, new applications.

Laser cleaning for cleaning electronic components

Another benefit of laser cleaning is its versatility. It can be used to clean a wide range of electronic components, including circuit boards, connectors, and sensors. The focused laser beam can target specific areas of a component, ensuring thorough cleaning without affecting nearby components.

Additionally, laser cleaning is a fast and efficient process. It can remove contaminants quickly and effectively, reducing downtime and increasing productivity. This makes it an ideal cleaning method for high-volume manufacturing environments.

In conclusion, laser cleaning is a highly effective method for cleaning electronic components. Its non-contact nature, precision, and efficiency make it an ideal choice for delicate electronic parts. By using laser cleaning, manufacturers can ensure that their electronic components are free from contaminants and perform optimally.

- Non-contact cleaning method

- Precision cleaning

- Environmentally friendly

- Fast and efficient

- Versatile cleaning method

- Contaminant removal

- Surface cleaning

- Electronic component cleaning

- High-volume manufacturing

- Delicate electronic parts

#laser #cleaning #electronic #components #precision #noncontact #environmentallyfriendly #efficiency

Laser cleaning for removing scale from pipes

How does laser cleaning work?

Laser cleaning works by using a high-energy laser beam to vaporize the scale buildup on the surface of the pipe. The intense heat generated by the laser breaks down the scale into its component parts, which are then easily removed with a blast of compressed air. This process is highly effective at removing even stubborn scale deposits, without causing any damage to the pipe itself.

The benefits of laser cleaning

There are several benefits to using laser cleaning for removing scale from pipes:

| Benefit | Description |

|---|---|

| Non-contact | Laser cleaning does not require any physical contact with the pipe, reducing the risk of damage. |

| Environmentally friendly | Laser cleaning does not use any chemicals or solvents, making it a safe and eco-friendly option. |

| Efficient | Laser cleaning can remove scale quickly and effectively, reducing downtime and maintenance costs. |

Applications of laser cleaning

Laser cleaning can be used in a variety of industries, including manufacturing, automotive, and aerospace. It is particularly useful for removing scale from pipes in industrial settings, where downtime and maintenance costs can be significant. By using laser cleaning, companies can improve the efficiency and longevity of their piping systems.

Conclusion

Laser cleaning offers a fast, efficient, and environmentally friendly solution to the problem of scale buildup in pipes. By using a high-energy laser beam to vaporize scale deposits, laser cleaning can effectively remove even stubborn deposits without causing any damage to the pipes themselves. This non-contact method is ideal for industries looking to reduce downtime and maintenance costs, while also improving the efficiency of their piping systems.

#laser #cleaning #scale #pipes #industrial #efficiency #environmentallyfriendly

słowa kluczowe: laser cleaning, scale removal, pipes, industrial, efficiency, environmentally friendly

frazy kluczowe: laser cleaning for removing scale from pipes, non-contact laser cleaning, environmentally friendly scale removal, efficient pipe cleaning.

Laser cleaning for cleaning glass surfaces

Another benefit of laser cleaning is its efficiency. Traditional cleaning methods can be time-consuming and labor-intensive, requiring multiple passes to remove stubborn stains and build-up. Laser cleaning, on the other hand, is fast and effective, often requiring just a single pass to completely clean the glass surface. This not only saves time and labor costs but also reduces the risk of damage to the glass.

Furthermore, laser cleaning is environmentally friendly. Unlike traditional cleaning methods that rely on harsh chemicals and abrasive materials, laser cleaning does not produce any harmful by-products or waste. This makes it a sustainable and eco-friendly cleaning solution that is safe for both the environment and the people using it.

In conclusion, laser cleaning is a cutting-edge technology that offers a safe, efficient, and environmentally friendly solution for cleaning glass surfaces. Its precision, efficiency, and eco-friendliness make it an ideal choice for a wide range of applications, from cleaning windows and mirrors to restoring historical glass artifacts. With the growing demand for sustainable cleaning solutions, laser cleaning is poised to become the go-to method for cleaning glass surfaces in the future.

- precision

- efficiency

- eco-friendly

- sustainable

- glass cleaning

- cutting-edge technology

- environmentally friendly cleaning

- historical glass artifacts

- delicate glass surfaces

- laser beam cleaning

#laser #cleaning #glass #surfaces #precision #efficiency #eco-friendly #sustainable #cutting-edge #technology #environmentally-friendly #historical #artifacts #delicate #laser-beam #cleaning

Laser cleaning for cleaning jewelry

Benefits of Laser Cleaning for Cleaning Jewelry

Laser cleaning is a non-contact cleaning method that uses a high-energy laser beam to remove contaminants from the surface of the jewelry. This method is gentle on the jewelry and does not require any harsh chemicals or abrasive materials. Some of the key benefits of laser cleaning for cleaning jewelry include:

| Benefits | Description |

|---|---|

| Non-contact cleaning | Laser cleaning does not require physical contact with the jewelry, reducing the risk of damage. |

| Precision cleaning | The laser beam can be precisely controlled to target specific areas of the jewelry for cleaning. |

| No damage to precious metals or gemstones | Laser cleaning is gentle on the jewelry and does not cause any damage to the materials. |

| No residue left behind | Unlike traditional cleaning methods, laser cleaning leaves no residue on the jewelry. |

How Laser Cleaning Works

Laser cleaning works by using a high-energy laser beam to vaporize contaminants on the surface of the jewelry. The laser beam is directed at the jewelry, and the energy from the beam causes the contaminants to evaporate without damaging the underlying materials. This process is highly effective at removing dirt, grime, and other contaminants from the jewelry.

Conclusion

Laser cleaning is a modern and efficient method for cleaning jewelry that offers many benefits over traditional cleaning methods. It is gentle on the jewelry, precise, and leaves no residue behind. If you want to keep your jewelry looking its best, consider using laser cleaning for your next cleaning session.

#laser #cleaning #jewelry #preciousmetals #gemstones #noncontactcleaning #precisioncleaning #nodamage #noresidueleftbehind

słowa kluczowe: laser cleaning, jewelry, precious metals, gemstones, non-contact cleaning, precision cleaning, no damage, no residue left behind

frazy kluczowe: laser cleaning for cleaning jewelry, benefits of laser cleaning, how laser cleaning works, modern cleaning method, gentle on jewelry, efficient cleaning technique, vaporize contaminants, remove dirt and grime, keep jewelry looking its best.

Laser cleaning for removing contaminants from 3D printed parts

One of the key advantages of laser cleaning is its versatility. It can be used on a wide range of materials, including plastics, metals, and ceramics. This makes it an ideal solution for manufacturers working with diverse materials in their 3D printing processes. Additionally, laser cleaning is a environmentally friendly method, as it does not require the use of harsh chemicals or solvents.

Another benefit of laser cleaning is its precision. The focused laser beam can target specific areas of the printed parts, ensuring that only the contaminants are removed without affecting the underlying material. This level of precision is crucial for maintaining the integrity of the parts and ensuring their functionality.

Overall, laser cleaning is a highly efficient and effective method for removing contaminants from 3D printed parts. Its versatility, precision, and environmental friendliness make it a valuable tool for manufacturers looking to improve the quality of their products.

Key benefits of laser cleaning:

- Efficient removal of contaminants

- Versatility in materials

- Precision targeting

- Environmentally friendly

Hashtags:

#3Dprinting #manufacturing #laser #cleaning #contaminants #precision #environmentallyfriendly

Keywords:

laser cleaning, 3D printed parts, contaminants, precision, efficiency, versatility

Long-tail phrases:

laser cleaning for 3D printed parts, removing contaminants with laser technology, benefits of laser cleaning in manufacturing

- Laser cleaning for removing contaminants from delicate surfaces - 29 February 2024

- Kanban vs Scrum – which method to choose? - 29 February 2024

- Minimum Viable Product – why it matters? - 26 November 2023